Calorimeter & Performance & System Test Bench

Compressor Calorimeter System (Belt type)

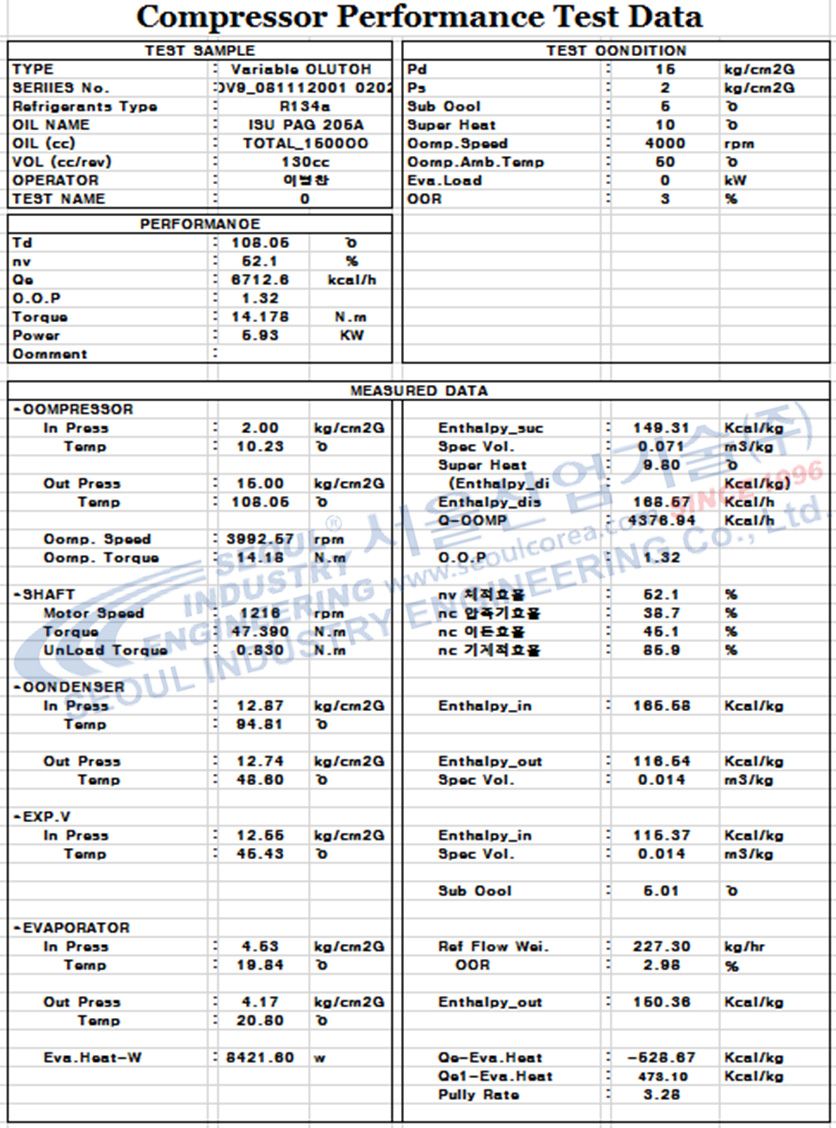

- Vehicle refrigerant compressor performance test to ISO 917

- System matching test

- Test of belt type compressor

Feature

- This calorimeter conforms to ISO917

- Performance test for vehicle refrigerant compressor

- Compressor condition setting & control

- The capacity, input power, COP, current, rotating speed, input power of inverters and temperature rise of windings can be determined

- Apply high precision pressure sensor

- Apply high precision temperature sensor

- High precision OCR control

- Automatic compressor speed control

- Data collection and computation through LabVIEW® automation software packages

- Be possible Variable data collection to DAQ system

Specifications

| MODEL | SEOUL-BDCCS-8848-1 Series |

|---|---|

| Compressor | |

| Capacity | 60cc~250cc/rev, 6,879kcal/h (8kW) |

| Temperature Control Range | RT∼120℃ ± 0.2℃ |

| Dischage Pressure (Pd) | ~ 4000 kPa (40 bar) ± 2 kPa (0.02 bar) abs. |

| Suction Pressure (Ps) | ~ 2000 kPa (20 bar) ± 2 kPa (0.02 bar) abs. |

| Super heat (SH) | 10℃ ±0.1℃ |

| Sub-cool (SC) | 5℃ ±0.1℃ |

| Compressor rpm (NC) | 0 ~12000 RPM (0 ~200Nm) |

| OCR | 0 ~3% |

| Calorimeter Unit (Evaporator) | 500 ~ 12,000kcal/h (18kw) ±0.1% |

| DC Power | 0 ~ 30VDC ( Clutch ) |

| Refrigeration | R134a , R123yf (Option R744) |

Construction / Control

| Construction | Control Room + Compressor Chamber |

|---|---|

| Control | Manual / Full Automatic |

| Control Interface | LabVIEW SoftWare with PC interface |

Apply high precision static pressure & differential pressure sensor of air side

Apply high precision RTD temperature sensor

Apply high precision coriolis type mass flow meter of liquid side

Real time density measurement

Refrigerant circulation system for condenser test

Compressor speed control for condenser test

Data collection and computation through LabVIEW® automation software packages

Be possible Variable data collection to DAQ system