Compressor Calorimeter System

(Belt & Electric) (1)

- Vehicle refrigerant compressor performance test to ISO 917

- System matching test

- Test of belt type and electric compressor

Feature

- This calorimeter conforms to ISO917

- Performance test for vehicle refrigerant compressor

- Compressor condition setting & control

- The capacity, input power, COP, current, rotating speed, input power of inverters and temperature rise of windings can be determined

- Apply high precision pressure sensor

- Apply high precision temperature sensor

- High precision OCR control

- Automatic compressor speed control

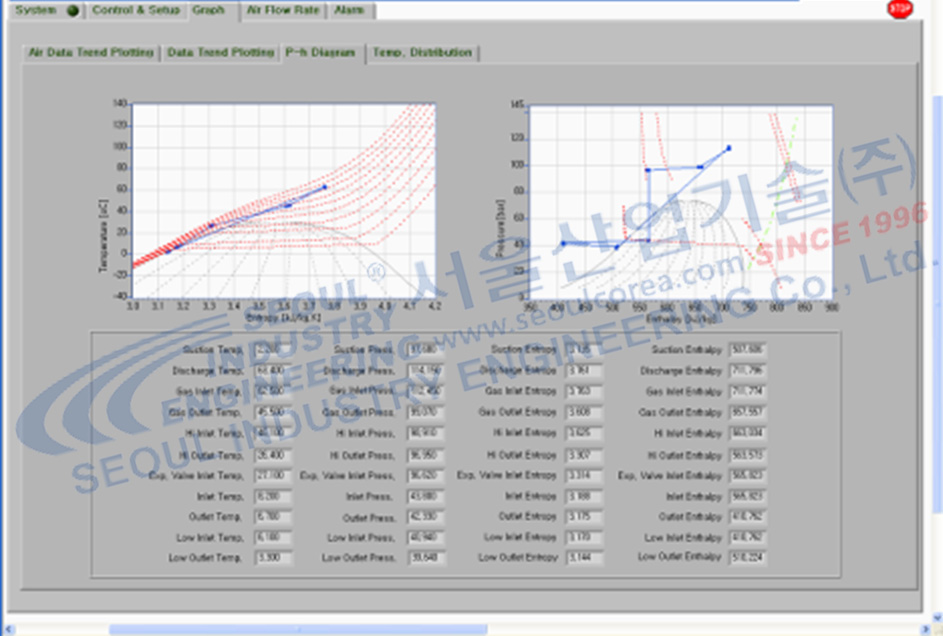

- Data collection and computation through LabVIEW® automation software packages

- Be possible Variable data collection to DAQ system

Specifications

| MODEL |

SEOUL-BEDCCS-8848-1 Series |

|

Compressor |

Eletric Compressor |

| Capacity |

60cc~250cc/rev, 6,879kcal/h (8kW) |

15cc~35cc/rev, 6,879kcal/h (8kW) |

| Temperature Control Range |

RT∼120℃ ± 0.2℃ |

| Dischage Pressure (Pd) |

~ 4000 kPa (40 bar) ± 2 kPa (0.02 bar) abs. |

| Suction Pressure (Ps) |

~ 2000 kPa (20 bar) ± 2 kPa (0.02 bar) abs. |

| Super heat (SH) |

10℃ ±0.1℃ |

| Sub-cool (SC) |

5℃ ±0.1℃ |

| Compressor rpm (NC) |

0 ~6000 RPM (0 ~200Nm) |

0 ~9000 RPM |

| OCR |

0 ~3% |

| Calorimeter Unit (Evaporator) |

500 ~ 12,000kcal/h (18kw) ±0.1% |

| DC Power |

0 ~ 30VDC ( Clutch ) |

~ 600 VDC 35A ( Motor ) |

| Refrigeration |

R134a , R123yf (Option R744) |

Construction / Control

| Construction |

Control Room + Compressor Room |

| Control |

Manual / Full Automatic |

| Control Interface |

LabVIEW SoftWare with PC interface |