Calorimeter & Performance & System Test Bench

Air Conditioning System Durability

Test Bench System (Belt)

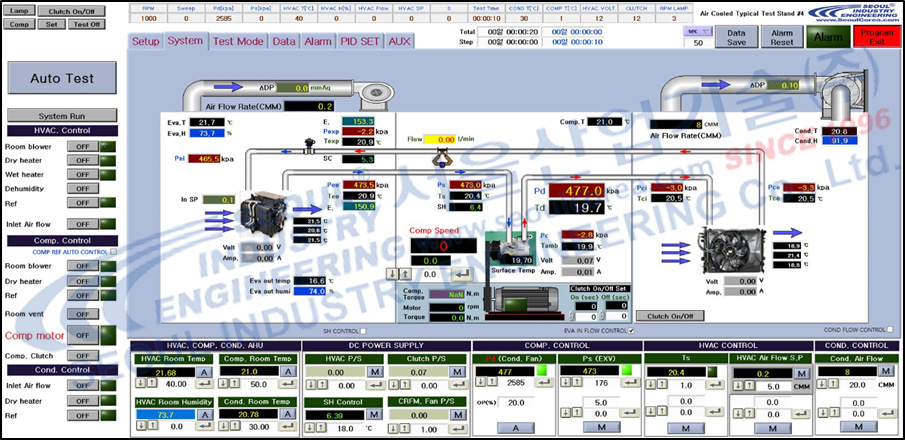

- A/C system performance test

- Evaporator performance test

- Condenser Durability Test

- Compressor Durability Test

- System matching test

- Test of belt type compressor

Feature

- Vehicle A/C system equipment test to conforms ISO 917

- A/C system test condition setting & control

- Air speed test for condenser

- Coolant flow & Temperature control

- Measuring comp. torque by torque detector

- Apply high precision pressure sensor

- Apply high precision temperature sensor

- High precision OCR control

- Blower RPM measuring

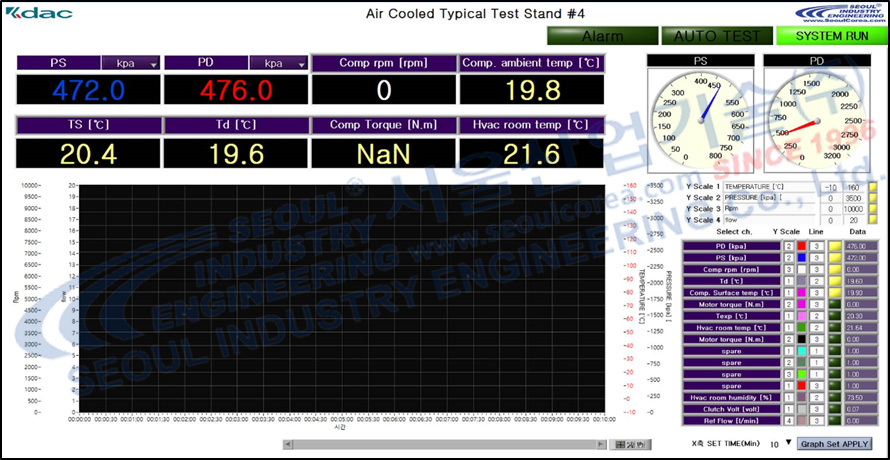

- Data collection and computation through LabVIEW® automation software packages

- Be possible Variable data collection to DAQ system

Specifications

| MODEL | SEOUL-ASDT-8848-1Series |

|---|---|

| Condenser Room Control | Temperature : -20 ~ 80℃ , ±0.5℃ Humidity : 20 ~ 90%RH (20 ~ 60℃,±5%) |

| Evaperator Room Control | Temperature : -20 ~ 80℃ , ±0.5℃ Humidity : 20 ~ 90%RH (20 ~ 60℃,5%) |

| Compressor Room Control | -10 ~ 120℃ , ±0.5℃ |

| Compressor Speed | 0 ~ 12000 RPM |

| Compressor Torque | 0 ~ 200 N.m |

| condenser Velocity | 0 ~ 15m/s (at 0.32m×0.32m, 5m/s, Pressure : 20mAq) |

| Comp Pressure | Discharge : 0 ~ 4000 kPa-abs., Suction : 0 ~ 2000 kPa-abs |

| HVAC Control | Power Supply (30V,50A) , Programmable Type |

| Refrigerant | R134a , R123yf (Option R744) |

Construction / Control

| Material | Control PANEL + Compressor +condenser + Evaporator Chamber |

|---|---|

| Test Room | Condenser room : 3000(L) × 2800(D) × 3200(H) Evaperator room : 5000(L) × 2800(D) × 3200(H) |

| Control | Manual / Full automatic |

| Control Interface | Directreading / LabVIEW softWare with PC interface |