Heat Pump System Test Bench

& Comfornents Calorimeter System

New Eco-Friendly Heat pump system test bench & Calorimeter system

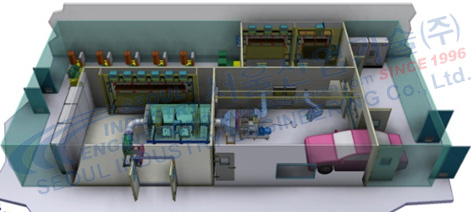

- Heat pump system performance test (Heating & cooling)

- A/C system performance test

- Evaporator performance test

- Condenser performance test

- Compressor preformance test (Belt & Electric)

- PTC heater & Inner condenser performance test

- System matching test

Feature

- High precision air flow measurement of flow nozzle type (ASHRAE Standard)

- Measuring comp. torque by torque detector

- Blower RPM measuring

- Electric heating & Steam injection system

- Each room environment control

- Calculate efficiency, compressor power Enthalpy, Entropy, Sub Cool, Superheat Specific volume, Heat balance

- Apply high precision pressure sensor

- Apply high precision temperature sensor

- High precision OCR control

- Programmable DC power supply

- Blower RPM measuring

- Data collection and computation through LabVIEW® automation software packages

- Be possible Variable data collection to DAQ system

Specifications

| MODEL |

SEOUL-HPSTB-8848-2Series |

|

Compressor |

condenser |

Evaporator |

| Capacity |

6,879kcal/h (8kW) |

30,000kcal/h(34kw) |

20,000kcal/h(17kW) |

| Temperature Control Range |

|

-30 ~60℃ |

-30 ~60℃ |

| Accuracy |

± 0.2℃ |

| Humidity Control Range |

|

30 ~ 90% RH (at -20~5℃) |

30 ~ 90% RH (at 10~50℃) |

| Accuracy |

± 2% |

| Comp.Room Control Range |

RT∼120℃ |

| Accuracy |

± 0.2℃ |

| Air Flow Rate |

|

500 ~ 12000CMH |

30 ~ 1200CMH |

| Compressor Speed |

0 ~12000 RPM (Belt & Electric DCV1000) |

| Compressor Torque |

0 ~200Nm |

| Coolant Flow Rate Range |

Upto ~ 100 ℓ/min ( 6,000 ℓ/h) |

| Coolant Temperature Range (at EG 50%) |

-30~120℃ |

| Accuracy |

± 0.2℃ |

| Refrigeration |

R134a , R123yf (Option R744) |

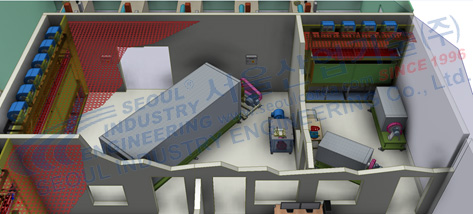

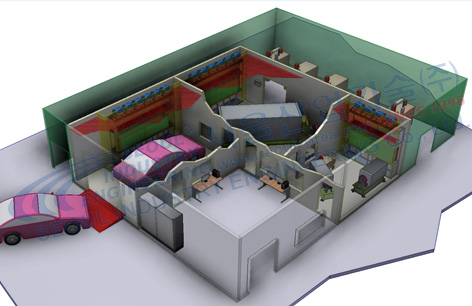

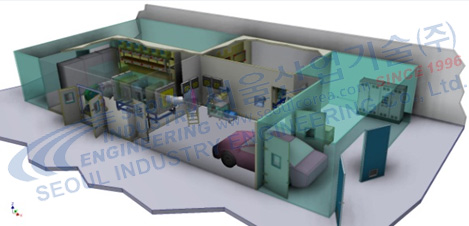

Construction / Control

| Construction |

Control Room + Compressor Room +condenser Room + Evaporator Room |

| Control |

Manual / Full Automatic |

| Control Interface |

LabVIEW SoftWare with PC interface |